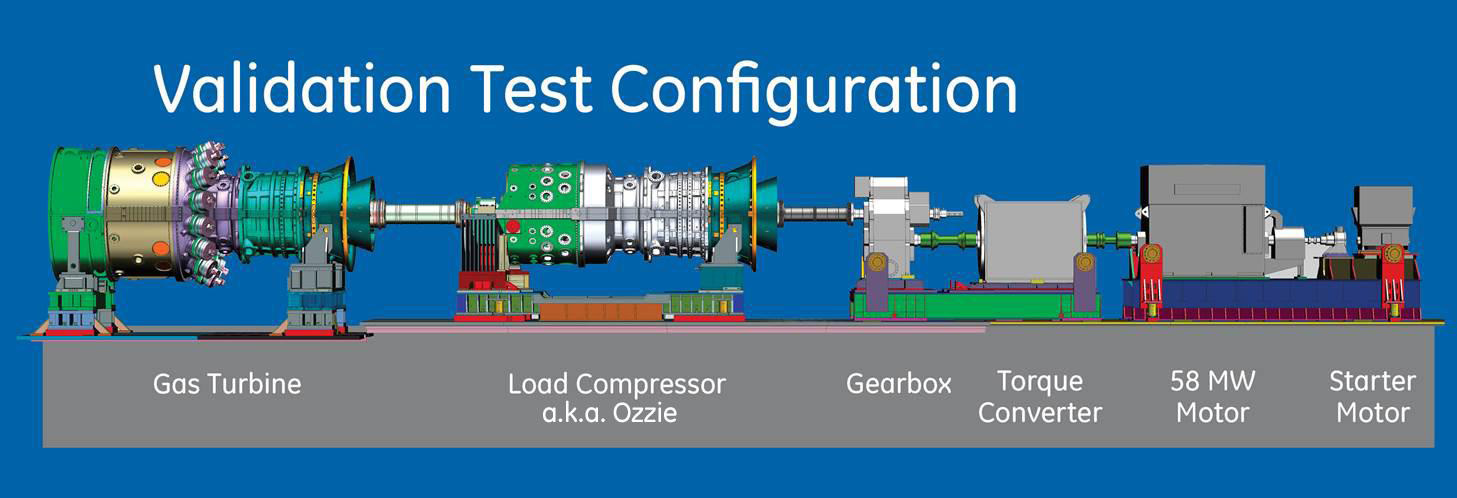

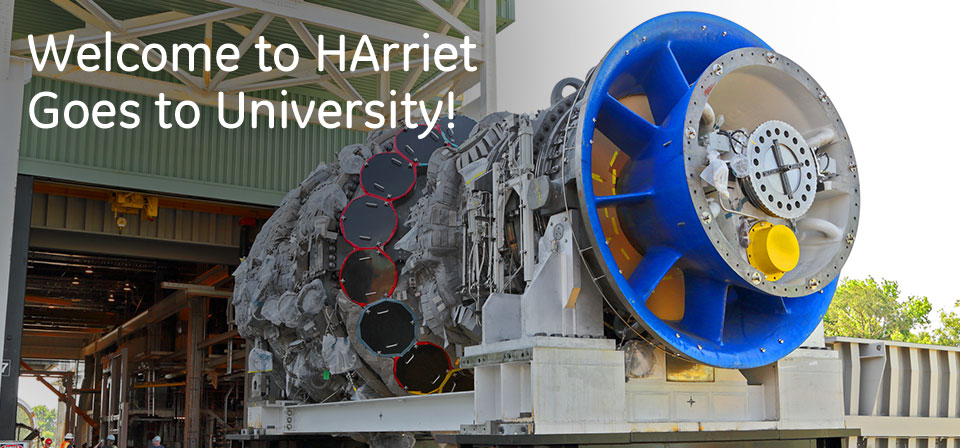

GE’s HArriet – one of the most efficient gas turbines in the world – is being sent to University! During these eight weeks, we will share with you her validation test plan, why we’re assessing her and how she performs.

HArriet will be tested on subjects from aero-mechanics and combustion mapping to grid compliance. Over the course of her testing, HArriet will be pushed to perform at all levels, as we prepare to send her off into the real world ready for the challenges she may face.